The STANLEY? Assembly Technologies B-Series Cordless Torque Tools are transducer-controlled battery powered tools that are ideal for threaded fastening assembly. STANLEY? delivers improved productivity and quality with performance-driven torque tool solutions for the assembly floor.

Our cordless B23LA Lever Tool is transducer-controlled battery powered tool for threaded fastening assembly. The long-life battery allows the operator to work productively and efficiently without the hassle, hazards, and potential damage from cables in the workplace.

The B23LA Lever Tool is part of the B Series cordless assembly tool product line. The B Series cordless torque tools are an extension of the QPM electric torque tool family and feature a closed-loop transducer control, as well as a brushless DC motor that delivers high performance and reliability. Common parts between these product lines offer low service and maintenance costs.

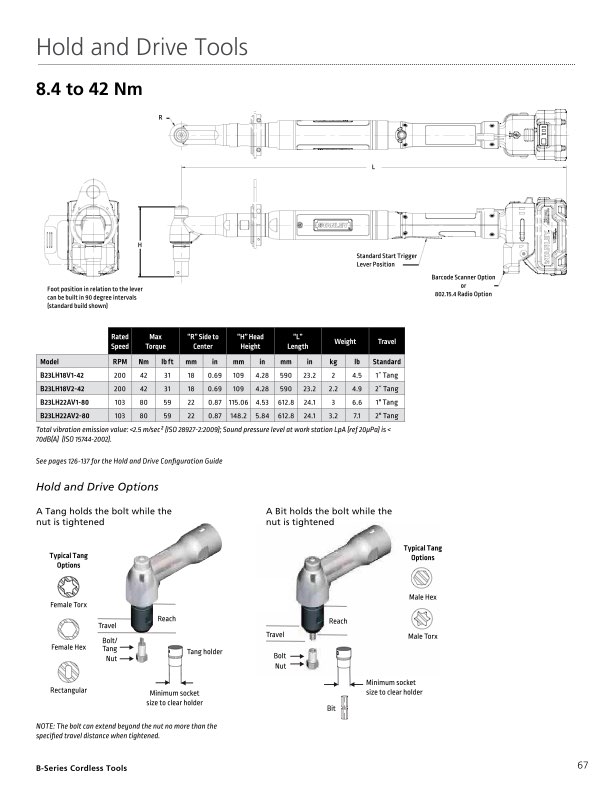

This tool is also available in specialty outputs: Flush, Crowfoot, Tube Nut, Hold and Drive, Safe Hold and Drive, Inline, and Offset.

Fast Facts:

The lightest weight cordless torque tool in this class of product.

One of the smallest sized solutions available.

Well-balanced with an operator-friendly design for increased productivity.

Provides visual and audible operator feedback.

Closed-loop transducer control and brushless DC motor deliver high performance and reliability.

Shipped with one battery pack and one charger.

Additional battery packs and chargers may be ordered separately.

Specifications:

105 ? 665 RPM Range

12, 17, 23, 35, 42, 52, 70, and 95 Nm

3/8″ (SD) Standard Output on 12 ? 42 Nm) and _” (SD) Standard Output on 52 ? 95 Nm

Output Options: _” QC on 12 and 17 Nm, _” SD on 23, 35, and 42 Nm

Weight:

4.3 lbs (1.95 kg) on 23 Nm

4.4 lbs (1.98 kg) on 35 Nm

4.6 lbs (2.11 kg) on 42 Nm

5.1 lbs (2.32 kg) on 52 Nm

5.5 lbs (2.95 kg) on 70 and 95 Nm