Featherweight Tooling has been used in industrial applications for many years to reduce weight over traditional round tooling by up to 70%. Lighter weight makes it easier, faster and more ergonomic to adjust during change over. The decrease in tooling weight can also increase the robot’s capacity to move at a much faster speed or handle more cups, or payload.

Norgren’s material handling group has built on the inherent strengths of featherweight tooling to introduce modular tooling and mounting structure systems to incorporate easy, durable and lightweight position mounting solutions for all applications.

These new tooling systems allow user friendly integration of vision, cameras, sensors, and dispensing systems to assembly, material handling, material detection and welding applications across all industries.

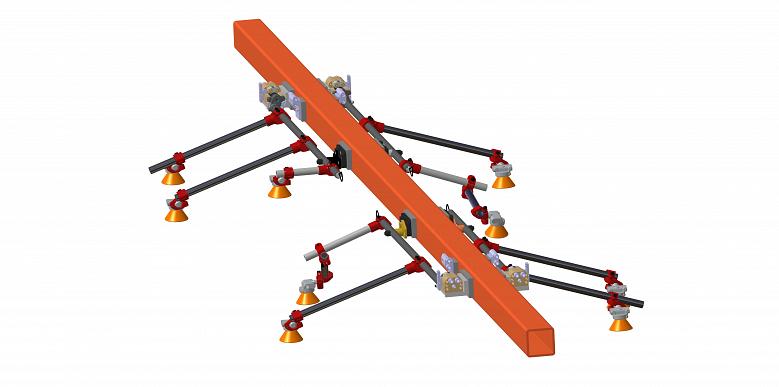

COBOT end-of-arm-tooling kit

The rise in popularity of Cooperative Robots – Cobots – has brought accessible robotics to a variety of applications where traditional robots were impractical or impossible for a variety of reasons.

Norgren has taken user friendly, easy implementation to heart in developing their featherweight Cobot End-Of-Arm-Tooling kit.

Many options are available to suit any application, including cobot adapter plates, vacuum cup mounts and ventruis, vacuum cups, and poka-yoke and vision mounting provisions.

modular mounting solutions kit

Norgren’s material handling group introduces modular tooling and mounting structures systems to incorporate easy, durable and lightweight position mounting solutions for all applications.

Norgren tooling systems allow user friendly integration of vision to assembly, material handling, material detection and welding applications across all industry.

featherweight tooling components

Norgren Featherweight Tooling is up to 70% lighter than the traditional round tooling, making it easier, faster and more ergonomic to adjust during change over. The decrease in tooling weight can also increase the robot’s capacity to move at a much faster speed or handle more cups. It can be used for a wide range of applications including Crossbar and Tandem press lines, industrial robotics, material handing, manipulators, and more.

Featherweight tooling components are available individually, or Rapid Assembly can provide engineering and assembly services to provide you with a turn-key tooling solution to fit your needs.